Improve Operations with Aftermarket Construction Parts

Improve Operations with Aftermarket Construction Parts

Blog Article

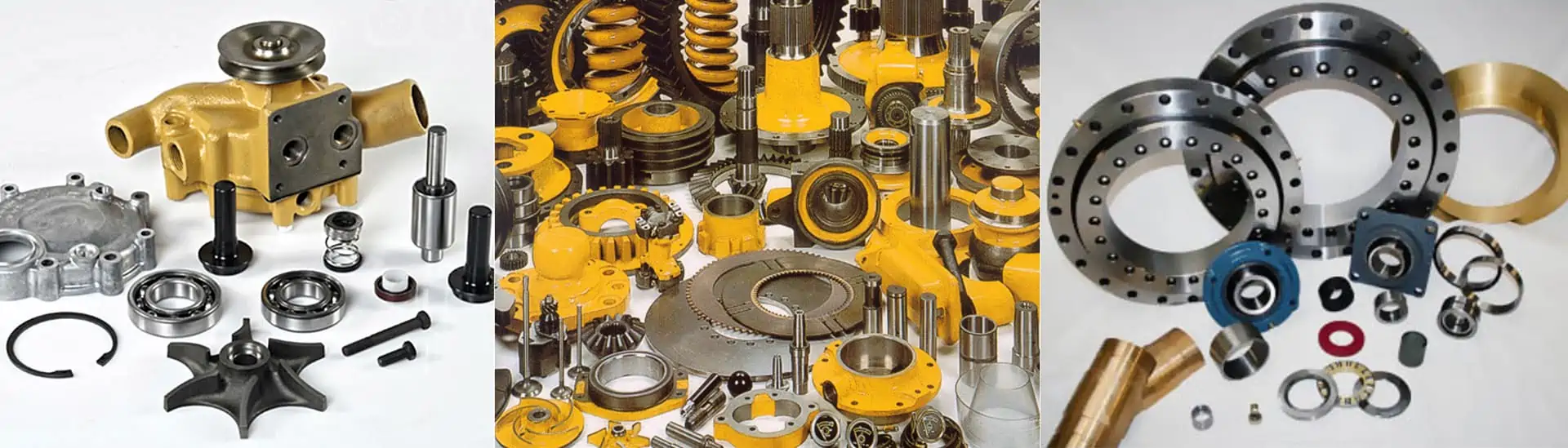

Discover Trusted Aftermarket Building Components to Maximize Your Heavy Machinery

Choosing for aftermarket construction components can be a critical decision for many businesses looking for to enhance their equipment efficiency while handling costs properly. Remain tuned as we explore the subtleties of discovering trustworthy aftermarket building and construction parts and just how they can raise the functionality of your hefty machinery.

Advantages of Aftermarket Building Components

Aftermarket building components use an affordable solution for preserving and repairing heavy equipment without jeopardizing on quality. One of the key benefits of making use of aftermarket building components is the significant price savings they supply compared to OEM (Original Devices Supplier) parts. These financial savings can be especially helpful for businesses aiming to reduce repair and maintenance expenditures without sacrificing the performance or long life of their heavy machinery.

In addition, aftermarket construction parts often use a bigger selection and accessibility than OEM components, permitting more versatility in sourcing the called for components rapidly. This access can aid minimize downtime for machinery, inevitably boosting operational effectiveness and performance. Moreover, aftermarket parts are usually generated by reliable producers who comply with sector criteria, ensuring that the quality and compatibility of these parts meet or exceed the requirements of the original equipment.

Factors to Consider When Choosing Components Distributors

When reviewing possible suppliers for building and construction parts, it is necessary to analyze their integrity, high quality criteria, and compatibility with the hefty machinery being serviced. Reliability is essential as it makes sure timely shipment of components, decreasing devices downtime. Providers with a proven track document of supplying exact and constant parts are more probable to meet your demands effectively.

Quality standards play a substantial function in the efficiency and durability of aftermarket parts. Go with providers that comply with industry laws and requirements, as this guarantees the longevity and integrity of the parts provided. Additionally, performing extensive research on distributors' quality assurance processes can aid you make a notified decision.

When choosing parts distributors,Compatibility with the heavy equipment being serviced is a key factor to consider. Parts that are specifically designed for your devices make certain a proper fit and ideal efficiency. Verify that the vendor offers parts that work with your equipment's make and model to prevent any kind of operational problems. By focusing on reliability, high quality criteria, and compatibility, you can choose a credible parts vendor that fulfills your construction devices requires properly.

Importance of Quality Control in Aftermarket Components

Quality assurance is a crucial part in guaranteeing the integrity and performance of aftermarket components for heavy equipment. When it comes to hefty equipment, the high quality of aftermarket components directly affects the effectiveness and longevity of the devices. Producers of aftermarket components must follow rigorous quality control procedures to meet market criteria and ensure that their products are long lasting and trusted

Quality assurance in aftermarket parts includes strenuous screening procedures to verify the performance, longevity, and compatibility of the components with various heavy equipment designs. By keeping high-quality requirements, aftermarket parts vendors can infuse self-confidence in consumers regarding the reliability of their products.

Buying aftermarket parts that have gone through detailed high quality guarantee procedures can result in cost savings in the future. Dependable find more information parts decrease the danger of unforeseen malfunctions, lessen downtime, and add to the general efficiency of heavy machinery operations. Therefore, when sourcing aftermarket parts for hefty equipment, focusing on vendors that focus on quality control can lead to optimal efficiency and performance.

Tips for Identifying Genuine Aftermarket Components

Enhancing Machinery Performance With Aftermarket Parts

Exactly how can aftermarket components add to enhancing the performance of heavy equipment? Aftermarket parts play a vital role in improving the efficiency of heavy equipment by supplying an affordable choice to original equipment maker (OEM) components. These parts are developed to fulfill or go beyond the standards set by OEM parts, ensuring compatibility and performance with different hefty machinery models. By utilizing aftermarket components, equipment drivers can access a large range of choices customized to details needs, such as improved toughness, raised efficiency, or enhanced performance.

Furthermore, aftermarket parts are typically quicker available than OEM components, decreasing downtime for maintenance and repair work. This availability enables machinery operators to swiftly address concerns and maintain their devices performing at peak performance levels. Additionally, aftermarket components can use ingenious options that may not be available via OEM carriers, making it possible for equipment owners to customize and maximize their tools according to certain requirements.

Conclusion

In verdict, aftermarket construction components offer different benefits and can enhance hefty machinery efficiency. Genuine useful link aftermarket components can boost machinery efficiency and resilience.

One of the key benefits of using aftermarket building and construction parts is the considerable price savings they supply compared to OEM (Original Devices Supplier) parts.Furthermore, aftermarket building and construction parts usually offer a broader option and availability than OEM parts, allowing for even more flexibility in sourcing the needed elements promptly. Aftermarket parts are usually generated by reliable makers that stick to industry standards, guaranteeing that the top quality and compatibility of these components fulfill or exceed the requirements of the original devices.

Report this page